A Genetic Algorithm Based Approach for Campus Equipment Management System in Cloud Server

Yu-Cheng Lin

1. Introduction

In recent years, the Internet and related technologies are constantly renewed from the form of cable connections of Internet to wireless Internet access, and the patterns of changes in Internet access to information become quicker.These changes are not only technological breakthroughs,but a completely new way of living. As ways to access the Internet get more diversified and more prevalent, applications are also becoming more extensive. Now we can learn knowledge, manage assets, and exchange information via Internet, which has brought great convenience to our lives.Radio frequency identification (RFID) is now one of the best examples of how wireless communication technology is rapidly changing the way we live. When consumers pushed their trolley full of merchandise towards the supermarket’s counter, without any calculations from the cashier, the monitor would show relevant payment details within seconds. At the same time, related merchandise replenishment systems will also confirm the precise number of merchandise needed in the replenishment process. Such an automatic identification technology is already widely used in automatic assembly processes[1], shopping service systems[2], hotel management[3], logistic warehouse systems[4], publication recommendation systems[5], etc. The improvement on procedures and management efficiency will outweigh its cost if we an adopt RFID technologyoriented information processing system.

Now the RFID identification system is widely used in campus such as active digital learning, student safety management, smart classroom management, library management, school bus positioning systems, e-wallet,parking management, and so on. This study will combine broadband wireless technology with RFID’s powerful identification ability to apply on equipment management in campus. This would break previous barriers of single-point model and achieve ubiquitous-management (U-Management). U-Management in a way can be seen as further development of mobile-management (M-Management) and electronic-management (E-Management). Therefore, some may think that U-Management = E-Management +M-Management.

It is difficult to maximize the utilization of the campus equipment if we use general permutation or random combination. Therefore, we propose a genetic algorithm based approach to maximize the utilization of the campus equipment.

2. Problem Formulation

The main purpose of this study is to improve campus facility management and to maximize the utilization of the campus equipment. Thus the structure of this study is divided into two major parts: the first part focuses on campus facility management graphical user interface (GUI)developed. The second part focuses on the equipment utilization. We will use data including the number of users,time periods, and available equipment to calculate the equipment utilization.

The RFID system we adopted has tags of 2.45 GHz frequency only. The purpose of using this microwave band tag is mainly due to its long-distance reading and higher sensitivity to environments, so it is more suitable to be used in merchandise management, supply chain management,baggage tracking, etc. In order to achieve the goal of efficiency and convenience, it is more favorable to use a single microwave band. This is an advantage in managing tags and it also makes full use of a single frequency reader which will avoid managing difficulty and reduce costs in a variety of tags and readers.

As RFID systems get more prevalent, its management model also becomes more diversified. Our system not only preserves previous relevant system characteristics but also concentrates on database access, process re-engineering,and error handling in extreme cases. We will provide more flexible modules for accessing data and also provide a wide range of ways to expedite the process. We then check the data consistency for improving data dependency. This study also provides mobile commerce in order to achieve ubiquitous way of management objectives as the core purpose of this architecture.

The data access architecture in our management system is divided into six layers. The first layer is the tier-based system which is the RFID database. Database contains personnel, equipment, and other related information. It also includes content-related procedures, such as the contents of the application form, error-handling procedures, and other related information. The second layer is the databasedependent layer. This layer plays an important role in transmitting data between the third layer and the first layer in real time. The third layer, making use of the characteristics of SqlDependency in Microsoft NET Framework 2.0, is the data cache layer and its main purpose is to pre-store information often queried by RFID database users. It can also shorten access time and improve the performance of database. The fourth layer is the data query layer, which is based on the most frequent queried RFID command to provide users a more convenient way to search the database. The fifth layer is the data table, which plays an important role in the user interface. When communication between data and the database is not frequent, the data table can be applied for browsing in offline mode. The final layer is the graphical user interface. Efficiency and easy use are the basic demands for a graphical user interface.

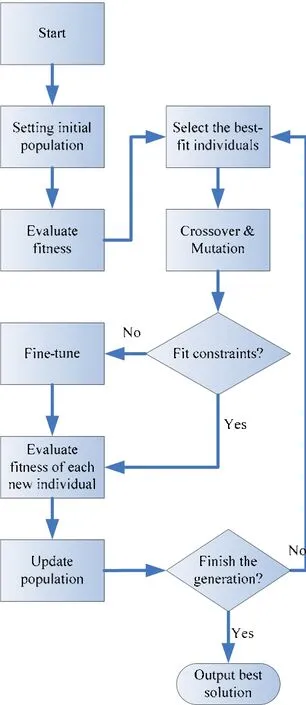

In this study, we use a server in particular as a demarcation point of information management process and receiving level, as depicted in Fig. 1. After entering the system, the user will first apply for the right to use the equipment. It is then transferred to the administrator to do a preliminary examination, and then the final submission to the audit for the final approval. This full coherent operation process is accompanied with personnel and asset management. Procedures such as data reception and cross match of relevant information are all done by using a server. Thus,the server plays a very important role and the requirement for the database is also essential. Detail documentation of every entry and situation can be matched with the database and also full disclosure relevant important information.

Fig. 1. Overview of the campus equipment management system.

In addition, the system can download data from the back-end of the database and calculate the total number of equipment being used and also the current number of usage requirements, and then compute the optimum solution for allocating campus equipment using genetic algorithm. The system would allow managers to adjust the usage of related equipment in order to enhance equipment utilization.

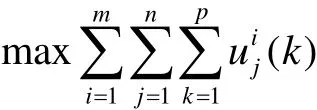

The problem of equipment utilization maximization is defined as follows:

subject to

where m denotes the number of equipment, n denotes the number of users, p denotes the number of time periods and ui(k)denotes that equipment i is occupied by user j at time

j period k. In the next section, the constraints will be described in detail.

3. Campus Equipment Management System

3.1 Genetic Algorithm Based Approach

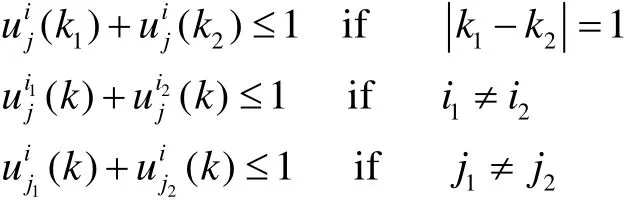

In this section, a genetic algorithm based approach will be proposed to maximize the utilization of the campus equipment. There are some issues that we should consider in our approach, for example, population initialization,fitness evaluation, selection, crossover, mutation,constraints verification, fine-tune, population update,stopping condition, and so on. The design flow of the genetic algorithm is shown in Fig. 2 and the following are the description of the approach in detail.

A. Population Initialization

During the initial procedure, the initial population of individuals would be chosen. Each individual is encoded with a bit string and each individual contains m×n×p genes where m denotes the number of equipment, n denotes the number of users, and p denotes the number of time periods.Each gene is randomly assigned to 0 or 1. Each individual will pass through the fine-tuning process if it is an infeasible solution. The population size is set to 80.

B. Fitness Evaluation

During this procedure, we evaluate the fitness of each individual in the population. In this paper, the equipment utilization is viewed as the fitness value.

C. Selection

During the selection procedure, we select the best-fit individuals for reproduction.D. Crossover and Mutation

New individuals are bred through crossover and mutation operations to give birth to offspring. The crossover rate is set to 0.5, and the mutation rate is set to 0.1.

E. Constraints Verification

In this paper, we assume that there are three restrictions.First, the same user shall not borrow the same equipment more than two time periods. Second, each user cannot use more than two pieces of equipment at the same time period.Third, each piece of equipment cannot be borrowed to more than two users at the same time period.

F. Fine-Tune

If an individual violates any restriction during constraints verification, the individual should pass through the fine-tuning process. In this stage, we choose the suitable genes and modify the content of genes until the individual is feasible.

G. Population Update

In this stage, we replace the least-fit population with new individuals.

H. Stopping Condition

The proposed approach terminates when finishing the generation. The generation number is set to 1400 as default.

3.2 Model of Intelligent Campus Equipment Ubiquitous-Management System

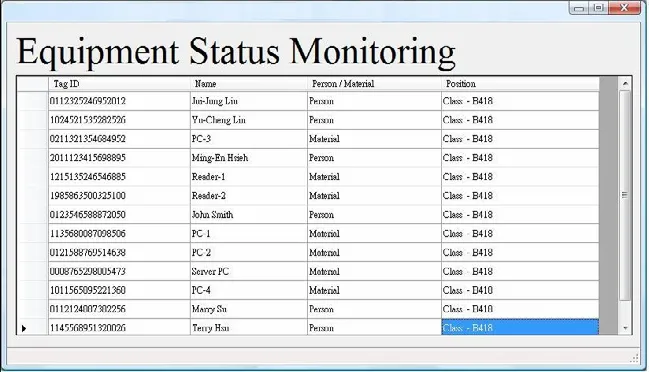

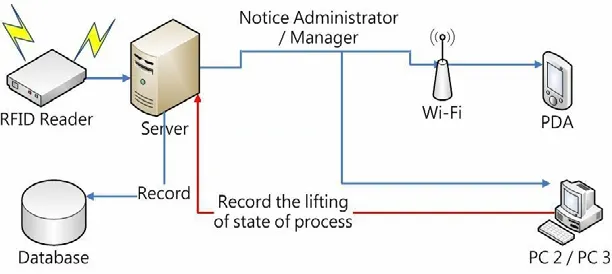

Users will leave detail records of their application to use certain equipment in the database. While the legitimate users access the permitted equipment, the premises reader will automatically read the user’s tag UID, and transmit to the server to check on the query and also record relevant information such as check-in time. Fig. 3 shows the running mode of intelligent campus equipment ubiquitousmanagement system and the actual RFID real-time monitoring is shown in Fig. 4.

Fig. 2. Design flow of the genetic algorithm based approach.

Fig. 3. Mode of intelligent campus equipment ubiquitousmanagement system.

Fig. 4. Real time monitoring of intelligent campus equipment ubiquitous-management system.

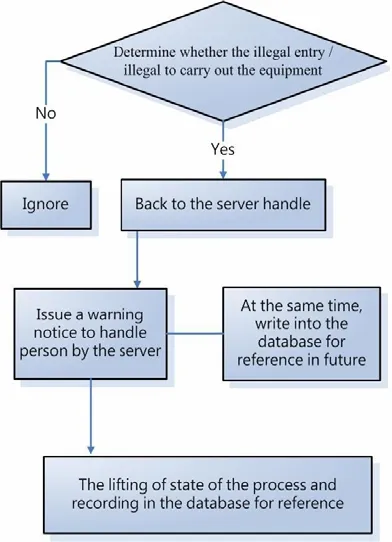

Fig. 5. Exception handling.

3.3 Mechanisms of Handling Extreme Case

Fig. 6 Schematic diagram of exception handling mechanisms.

When the situation of using campus equipment without approval occurs or equipment is carried beyond the authorized zone, the system will react according to a certain procedure. The intelligent RFID real-time monitoring system will keep on matching data with the back-end of the database. When a situation occurs, it will notify relevant personnel to take corresponding actions and also require the responsible personnel to key in the measured values. This approach can provide future reference, review relevant problems and also build up a knowledge base for dealing with special situations. The full procedure in handling the unexpected situations is shown in Fig. 5 and its mechanism is depicted in Fig. 6.

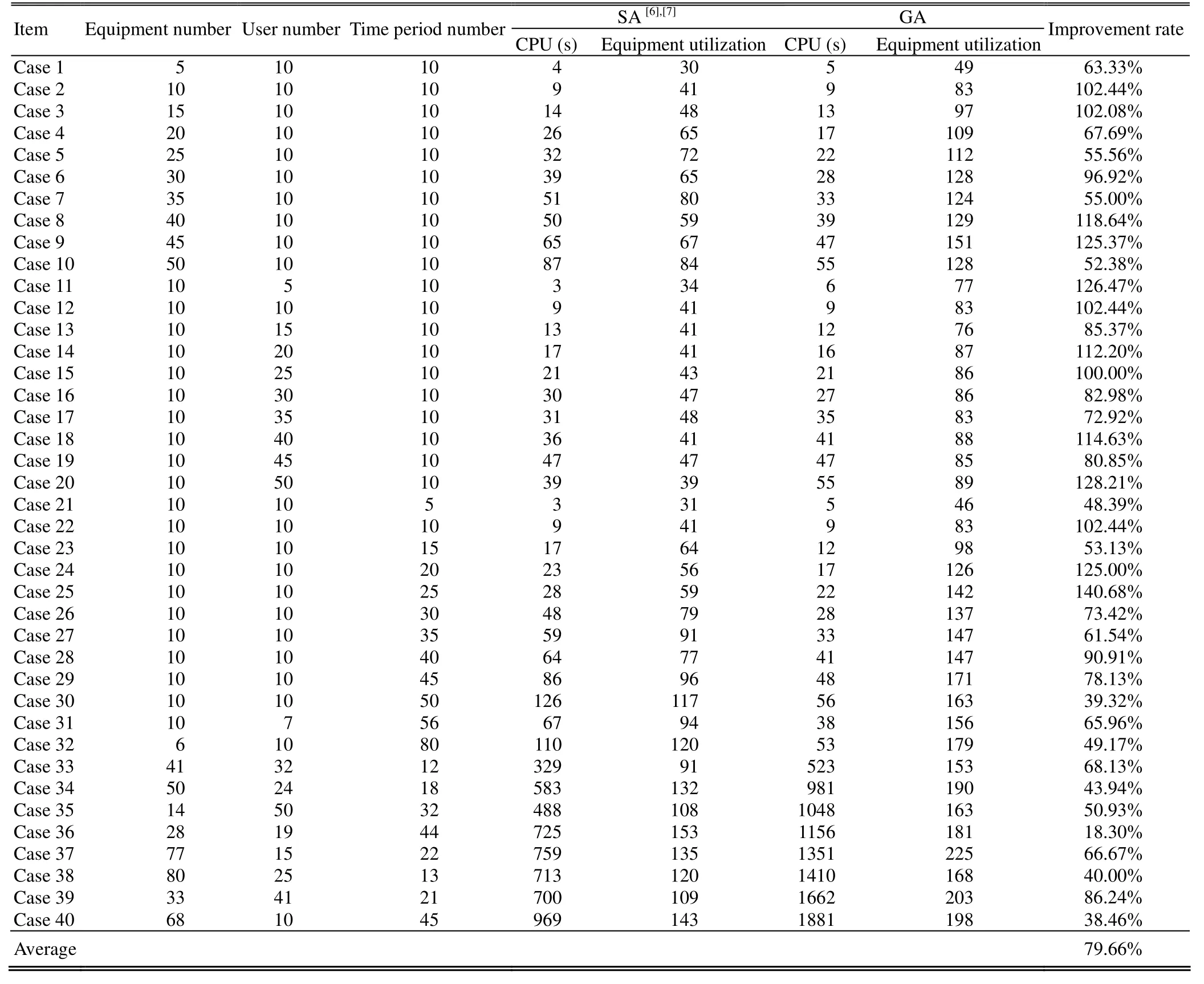

Table 1: Comparison of SA and Our GA Approach

4. Experimental Result

The proposed algorithm is implemented using C++language on an Intel 2.4 GHz CPU machine with 512 MB memory. We take the cases which are the same as [6], [7] to test our algorithm. Table 1 shows the comparison between our genetic algorithm based approach (GA) and simulated annealing based approach (SA) proposed in [6], [7]. There are 40 different test cases with variable number of equipment, users, and time periods. In Table 1, the first column denotes the test cases. The second column denotes the number of equipment, the third column denotes the number of users, and the fourth column denotes the number of time periods. “CPU (s)” and “Equipment utilization”represent the CPU run time in seconds and the equipment utilization, respectively. From the table, it shows experimentally that our GA approach achieves an average 79.66% improvement in equipment utilization in an acceptable run time.

5. Conclusions

From this study, we gained much better understanding of RFID. It is easy and convenient to apply RFID on ubiquitous management via Internet and a simple,easy-to-use system. RFID has great potential in improving existing management systems. However, some problems are still open, e.g., effective and efficient system integration and supplementary measures for issues like privacy are worthy of further research and consideration.

The purpose of using genetic algorithm in this study is to shorten the time to obtain a better solution and prevent infeasible solutions when there are many pieces of equipment and applicants logged in a system. From the experimental results, we can see that our genetic algorithm based approach can provide an excellent solution in limited time and effectively improve the drawbacks, such as timeconsuming and high cost.

[1] N.-K. Chung, “Application of RFID in auto assembly process,” M.S. thesis, Dept. Industrial Engineering and Engineering Management, National Tsing Hua University,Taiwan, 2007.

[2] T.-C. Chen, “An RFID-based shopping service system for retailers,” M.S. thesis, Dept. of Engineering Science,National Tsing Hua University,Taiwan, 2008.

[3] W.-C. Hung, “The application of RFID in hotel management,” M.S. thesis, Dept. of Engineering Science,National Cheng Kung University, Taiwan, 2006.

[4] C.-Y. Yang, “A study on the application of RFID on logistic warehouse system,” M.S. thesis, Dept. Institute of Traffic And Transportation, National Chiao Tung University,Taiwan,2007.

[5] J.-H. Cheng, “An RFID-based publication recommendation system,” M.S. thesis, Dept. Industrial Engineering and Engineering Management, National Tsing Hua University,Taiwan, 2006.

[6] M. E. Hsieh, “Development of an RFID-based intelligent school equipment management system,” M.S. thesis, Dept.Information and E-commerce, Kainan University, Taiwan,2009.

[7] J.-J. Liu, Y.-C. Lin, M.-E. Hsieh, and S.-J. Chen, “Using simulated annealing algorithm in the development of an RFID-based intelligent school equipment management system,” presented at the Int. Conf. on Business and Information, Kuala Lumpur, 2009.

Journal of Electronic Science and Technology2013年2期

Journal of Electronic Science and Technology2013年2期

- Journal of Electronic Science and Technology的其它文章

- Call for Papers Journal of Electronic Science and Technology Special Section on Terahertz Technology and Application

- JEST COPYRIGHT FORM

- ID-Based User Authentication Scheme for Cloud Computing

- Interpurchase Time of Customer Behavior in Cloud Computing

- Toward Cloud-Based Parking Facility Management System: A Preliminary Study

- A Distribution Management System for Relational Databases in Cloud Environments