Comparison of Benefits of Different Tobacco Loading Methods and Matching Baking Processes in Intensive Curing Houses

Yonghua CHEN, Hongquan SUN, Yongfeng AI, Jinzhong SHI, Pengzhen LONG, Guoquan LIU, Taiwei LIU

Guizhou Provincial Tobacco Company Tongren Branch, Tongren 554300, China

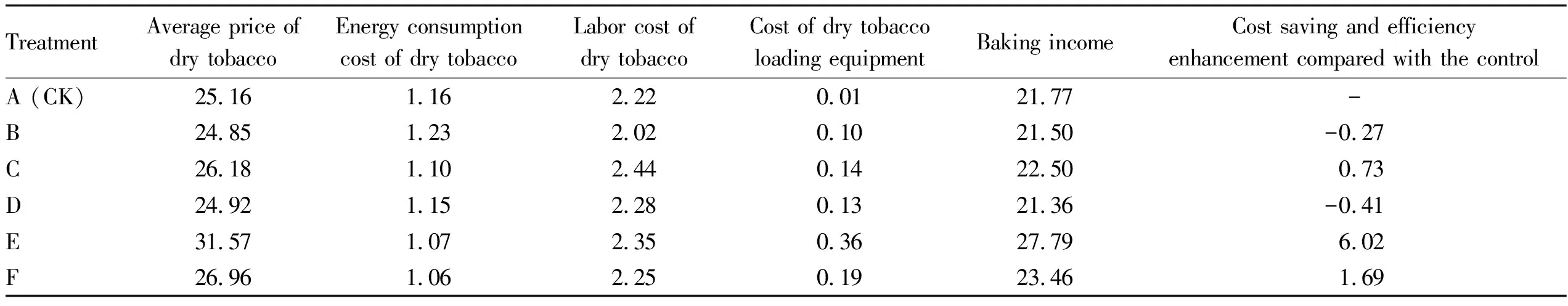

Abstract [Objectives]To compare the benefits of different tobacco loading methods and supporting baking processes in intensive curing houses.[Methods]Flue-cured tobacco variety K326 was taken as material, and comparative experiment on baking effects of six tobacco loading methods(traditional hanging pole, loose leaf stacking, loose leaf binding and inserting, loose leaf inserting, loose leaf net basket, loose leaf grid)was conducted.[Results]Cost of dry tobacco loading equipment for hanging pole and loose leaf stacking was 0.01 and 0.1 yuan/kg, and cost of tobacco loading by loose leaf basket reached 0.36 yuan/kg.Labor cost for baking dry tobacco by direct stacking of loose leaves reached 2.02 yuan/kg, which was the lowest, while labor cost for binding and inserting loose leaves reached 2.44 yuan/kg, which was the highest.Energy consumption cost of dry tobacco baking with loose leaf grid was 1.06 yuan/kg, which was the lowest, while baking energy consumption cost of loose leaf stacking reached 1.23 yuan/kg, which was the highest.From the perspective of baking income, loose leaf inserting reached 21.36 yuan/kg, which was the lowest, while net basket reached 27.79 yuan/kg, which was the highest, followed by grid(23.46 yuan/kg)and loose leaf binding and inserting(22.5 yuan/kg).[Conclusions]It is worth popularizing the loose leaf binding and inserting and the loose leaf grid baking.

Key words Flue-cured tobacco, Tobacco loading method, Intensive curing, Tobacco quality, Benefit

1 Introduction

In terms of the way to pack tobacco in the intensive curing house, foreign countries mainly use the cigarette holder to hold the tobacco, and some use the large oven to bake, while China still mainly uses the traditional tobacco pole to weave the tobacco[1-3].In recent years, with the development of modern tobacco agriculture in China, large-scale intensive curing houses have been promoted in an all-round way, and various regions have actively explored new tobacco packaging and curing methods in the tobacco leaf curing link.Relevant research reports gradually increased[4-8], which greatly enriched the theoretical basis of flue-cured tobacco curing and provided theoretical and technical basis for production and application.In 2012, baking effects of traditional tying rod, cigarette holder clamping and loose leaf stacking were studied[9].On this basis, baking effects of six tobacco loading methods(traditional hanging pole, loose leaf stacking, loose leaf binding and inserting, loose leaf inserting, loose leaf net basket, loose leaf grid)were studied in 2019.The research aimed to explore a more suitable tobacco loading method for the baking development of modern tobacco agriculture, and provide a theoretical basis for intensive baking supporting technology of "reducing work and cost, improving quality, and increasing efficiency" in modern tobacco agriculture.

2 Materials and methods

2.1 Test siteThe test was conducted in Tuoli Group of Yuquan Village of Heshui Town of Yinjiang County, and the geographical position is 108°34′01.5″ E, 28°00′47.2″ N.The altitude is 936 m, and the soil is yellow sandy loam.

2.2 Flue-cured tobacco varietyThe tested flue-cured tobacco variety was K326.Floating system was taken, and well cellar transplanting of young seedlings was conducted.

2.3 MethodsThe test set up six tobacco loading methods: traditional hanging pole, loose leaf stacking, loose leaf binding and inserting, loose leaf inserting, loose leaf net basket, and loose leaf grid, a total of 6 treatments(Table 1).Except that the traditional hanging pole adopted the "three-stage" baking process, the rest adopted the "loose leaf baking" process.

2.4 Measurement indexesCost of supporting equipment for cigarette loading: equipment cost of single curing room and dry tobacco loading equipment cost; volume of fresh tobacco loading, density of tobacco loading, and volume of dry tobacco after baking; grade quality, average price and single-leaf weight of flue-cured tobacco; labor quantity and labor cost for picking and baking; power and coal consumption cost for baking.

3 Results and analysis

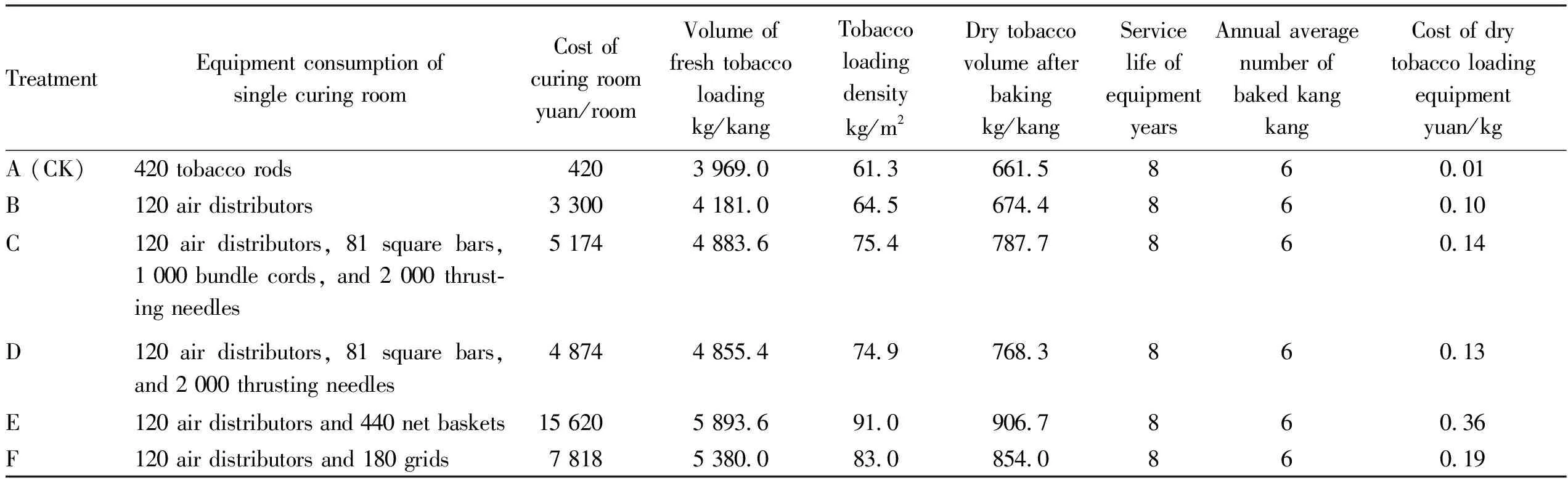

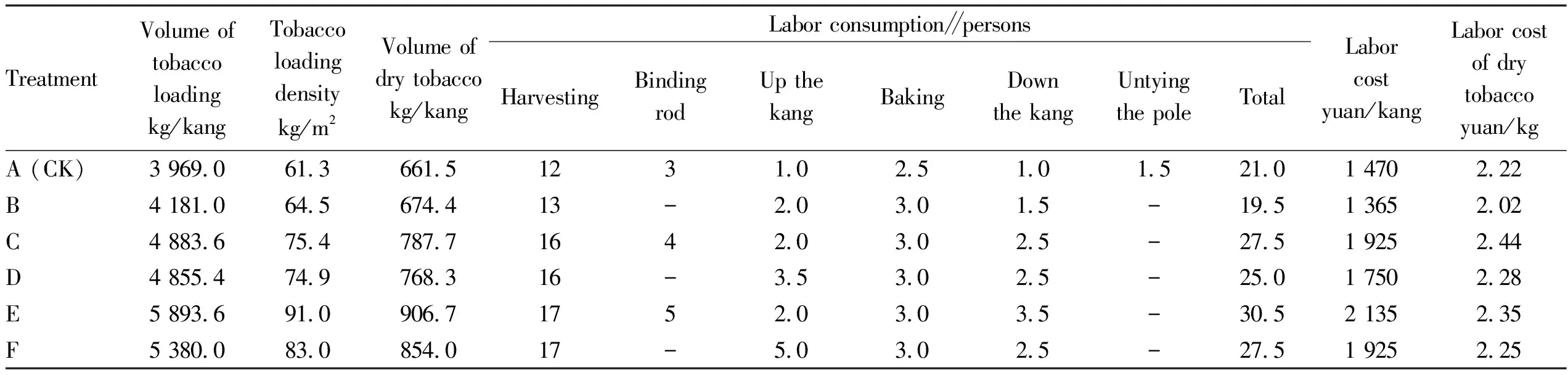

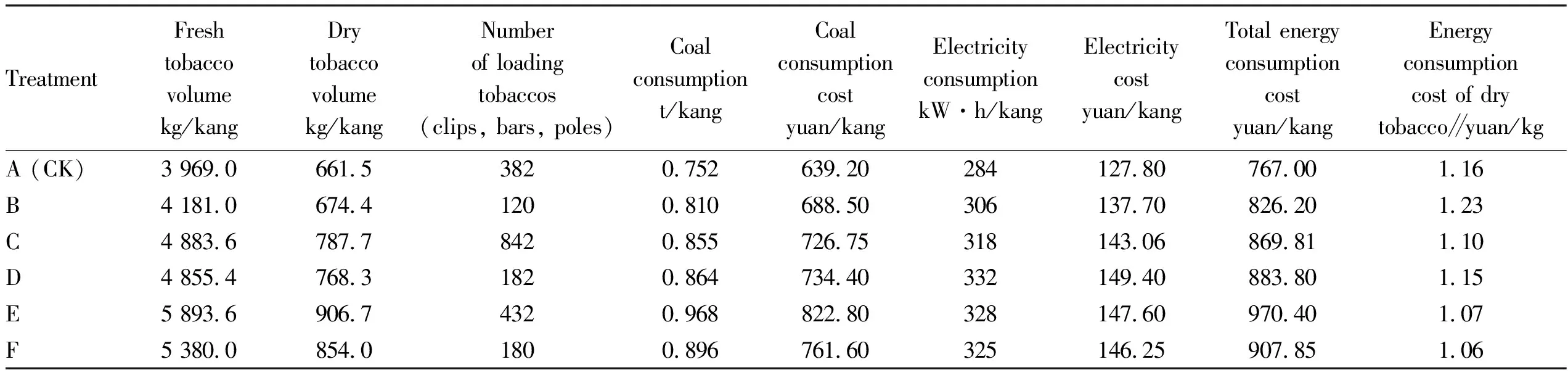

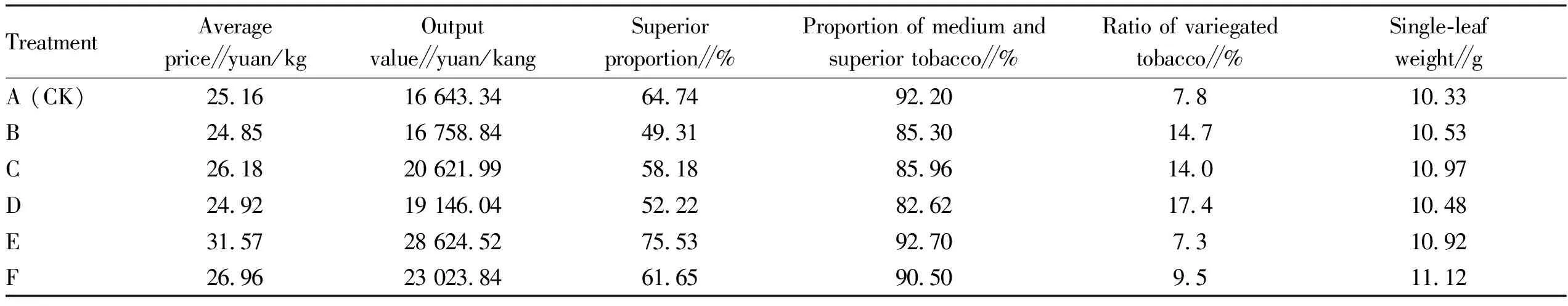

3.1 Cost of supporting equipment, tobacco loading volume and cost of dry tobacco equipmentSeen from Table 2, among the six tobacco loading methods, cost of supporting equipment for loading tobacco in single curing room was the lowest in the treatment A(420 yuan/room), while it was higher in the treatments B, C, D, and F, and the highest cost reached 15 620 yuan/room in the treatment E.The smallest tobacco loading density per room was 61.3 kg/m2in the treatment A, while it was higher in the treatments C, D, F, and the highest reached 91 kg/m2in the treatment E.Converted into the loading cost of dry tobacco, treatment A Table 1 Experimental design of different tobacco loading methods Table 2 Cost of supporting equipment, tobacco loading volume and cost of dry tobacco equipment for different tobacco loading methods 3.2 Labor cost for picking and bakingSeen from Table 3, 21 workers for picking and baking were used in the treatment A, and labor cost of dry tobacco was 2.22 yuan/kg, which was higher than the treatment B.The main problem was that treatment B did not need to tie the pole, but directly onto the kang.The labor cost of other treatments was higher than that of treatment A, mainly due to the increase of tobacco loading, and the increase of labor in harvesting and up and down the kang.Labor cost of dry tobacco was treatment B 3.3 Energy consumption costSeen from Table 4, energy consumption cost of dry tobacco by loose leaf stacking, loose leaf binding and inserting, loose leaf inserting, loose leaf net basket, and loose leaf grid was 1.23, 1.10, 1.15, 1.07 and 1.06 yuan/kg.The energy consumption cost of dry tobacco by loose leaf binding and inserting, loose leaf net basket and loose leaf grid was lower than that of the control, because the dry tobacco quantity baked was far greater than the energy consumption of the extended baking time. Table 3 Labor cost of different tobacco loading methods Table 4 Energy consumption cost of different tobacco loading methods 3.4 Economic characteristics of flue-cured tobaccoSeen from Table 5, average price of tobacco loaded by loose leaf net basket reached 31.57 yuan/kg, which was the highest.Average price of tobacco loaded by loose leaf stack for baking reached 24.85 yuan/kg, which was the lowest.The proportion of variegated tobacco was all higher than that of control A except E.In the treatment D, tobacco pole was used as fixed square pole when loading tobacco.During the baking process, because six square poles fell from the fixed slot, 36.2 kg tobacco leaves were not dried, so the proportion of variegated tobacco was as high as 17.4%. Table 5 Economic characteristics of flue-cured tobacco leaves with different loading methods Seen from Table 6, the treatments B and D was lower than the control A in cost saving and efficiency increasing, while other treatments were all higher than control.It was the highest in the treatment E, reaching 6.02 yuan/kg, followed by treatments F and C. Table 6 Cost saving and benefit increasing effects of different tobacco loading methods yuan/kg The six tobacco loading methods can meet the needs of baking.The tobacco loading methods of loose leaf stacking, loose leaf binding and inserting, loose leaf inserting, loose leaf net basket and loose leaf grid have changed the traditional tobacco loading methods and increased the amount of tobacco loading.The cost of dry tobacco loading equipment for hanging pole and loose leaf stacking is low, and the cost of loose leaf net basket is the highest.The labor cost for direct stacking of loose leaves to bake dry tobacco is the lowest, and the labor cost for binding and inserting loose leaves is the highest.The energy consumption cost of dry tobacco cured with loose leaf grid is the lowest, and that of bulk cured with loose leaf is the highest.From the perspective of baking income, loose leaf inserting is the lowest, while net basket is the highest, followed by grid and loose leaf binding and inserting.The one-time capital investment of the net basket is large, which is difficult to promote.According to comprehensive analysis, loose leaf binding and inserting and loose leaf grid baking are worth popularizing.

3 Conclusions

Asian Agricultural Research2022年10期

Asian Agricultural Research2022年10期