Three-Dimensional Metacomposite Based on Different Ferromagnetic Microwire Spacing for Electromagnetic Shielding

QIAO Ye(喬 也), JIANG Qian(姜 茜), UDDIN Azim, QIN Faxiang(秦發(fā)祥), WU Liwei(吳利偉)*

1 Tianjin and Ministry of Education Key Laboratory for Advanced Textile Composite Materials, Tiangong University, Tianjin 300387, China 2 Innovation Platform of Intelligent and Energy-Saving Textiles, School of Textile Science and Engineering, Tiangong University, Tianjin 300387, China 3 Institute for Composites Science Innovation(InCSI), School of Materials Science and Engineering, Zhejiang University, Hangzhou 310027, China

Abstract: An electromagnetic shielding metacomposite based on the absorbing mechanism was prepared by weaving ferromagnetic microwires into the three-dimensional(3D)fabric. The influence of the ferromagnetic microwire spacing on electromagnetic shielding performance and the electromagnetic shielding mechanism of 3D metacomposites were studied. The total electromagnetic shielding performance increases with the increase of electromagnetic wave frequency. 3D metacomposites based on the absorbing mechanism can avoid the secondary pollution of electromagnetic waves, and have great potential in military, civil, aerospace and other fields.

Key words: three-dimensional(3D)metacomposite; ferromagnetic microwire spacing; electromagnetic shielding; mechanism

Introduction

The rapid development of modern electronic industry not only provides convenience for people’s life, but also brings electromagnetic pollution[1-2].At present, electromagnetic interference(EMI)shielding materials are often used to reduce or eliminate the adverse effects of electromagnetic radiation[3].Traditional EMI shielding materials include metal-based materials and polymer composites.Although metal-based materials have high conductivity, their high density limits their application in advanced devices[4].The polymer composites filled with high content of fillers have high conductivity and EMI shielding performance.However, the poor mechanical properties and severe interface separation hinder their practical application[5].As we all know, the construction of conductive network is an important way to improve the electromagnetic shielding performance of composites.Textile fibers have good continuity, so how to use textile fibers and conductive fillers to build conductive network in composites becomes the research goal.Zhuetal.[6]increased the electrical conductivity of the composite by depositing Ni layer on carbon fiber(CF)surface.The results show that CF-Ni/epoxy composite has excellent mechanical performance and electromagnetic shielding performance, and the reflection is the main shielding mechanism.Although good electromagnetic shielding performance can be achieved by using the continuity of fibers and high conductivity of conductive particles, the impedance mismatch accompanied by the excellent electrical performance will reflect electromagnetic waves back to the environment, resulting in the secondary pollution of electromagnetic waves.Therefore, it is expected to obtain the electromagnetic shielding mechanism based on absorption in the pursuit of excellent electromagnetic shielding performance.Luetal.[7]used CF felt(CFF)to prepare flexible and intelligent CFF/poly(ethylene-co-vinyl)acetate EMI shielding composites.High absorption and low reflection is the shielding mechanism of the EMI shielding composite.Electromagnetic metamaterials have unique properties such as negative refraction and inverse Doppler effect, which make them show great potential in microwaves and electronic devices fields[8-9].Chengetal.[10]prepared EMI shielding metacomposites with tunable negative permittivity by using silver and silicon nitride.

A three-dimensional(3D)metacomposite with high absorption and low reflection is prepared.Quartz fibers and ferromagnetic microwires are combined to form preform by the 2.5D angle-interlock weaving method.Resin transfer molding(RTM)is used to composite the preform.The influence of the ferromagnetic microwire spacing on the electromagnetic shielding performance and the electromagnetic shielding mechanism of 3D metacomposites are studied.

1 Experiments

1.1 Materials

Quartz fibers have the characteristics of low dielectric loss and wave transmission, so it is used as preform material.Type D quartz fibers with a density of 2.2 g/cm3and fineness of 190×4 tex were provided by Hubei Feilihua Quartz Glass Co., Ltd., China.Ferromagnetic microwires with the diameter of 50 μm and the core diameter of 9 μm were produced by Taylor-Ulitovsky process[11].Epoxy resin TDE-86 and 70 anhydride were provided by Jingdong Chemical Composite Co., Ltd., China.

1.2 Preparation of 3D metacomposites

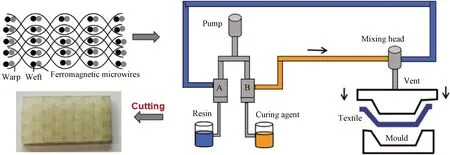

Type D quartz fibers were used in warp and weft directions of the perform.The ferromagnetic microwires were inserted along with the weft yarns during the 2.5D angle-interlock weaving process.Yarns were arranged in 192 rows×4 layers, and the warp density and the weft density were both 5 count/cm.Based on this weaving method, three ferromagnetic microwire spacings of 0.5, 1.0 and 2.0 mm were designed.The volume content of quartz fibers in the three 3D metacomposites is 0.87%, 1.74% and 3.49%, respectively.As shown in Fig.1, RTM was applied to fabricate the composites.The mould size was 380 mm×180 mm×2 mm.The ratio of epoxy resin TDE-86 to 70 anhydride was 1.000∶0.275.As shown in Fig.2, micro-CT was used to scan 3D metacomposites in order to further observe the morphological characteristics.

Fig.1 Fabrication flow chart of 3D metacomposites

Fig.2 Micro-CT image of 3D metacomposites

1.3 Testing method and devices

TheSparameters of X band and Ku band were measured by a Rohde & Schwarz vector network analyzer(Munich, Germany).Rectangular WR-90 waveguide with the testing size of 22.68 mm×10.16 mm×2.00 mm was used in X band[12].Rectangular WR-62 waveguide with the testing size of 15.799 mm×7.899 mm×2.000 mm was used in Ku band.The electromagnetic shielding performance of 3D metacomposites was calculated by theSparameters tested.The specific calculation formulas are[6]

(1)

(2)

SET=-10lnT,

(3)

SER=-10ln(1-R),

(4)

(5)

whereRis the reflectivity,Tis the transmittance,SETis the total electromagnetic shielding effectiveness(SE),SERis the reflection loss effectiveness, andSEAis the absorption loss effectiveness.

2 Results and Discussion

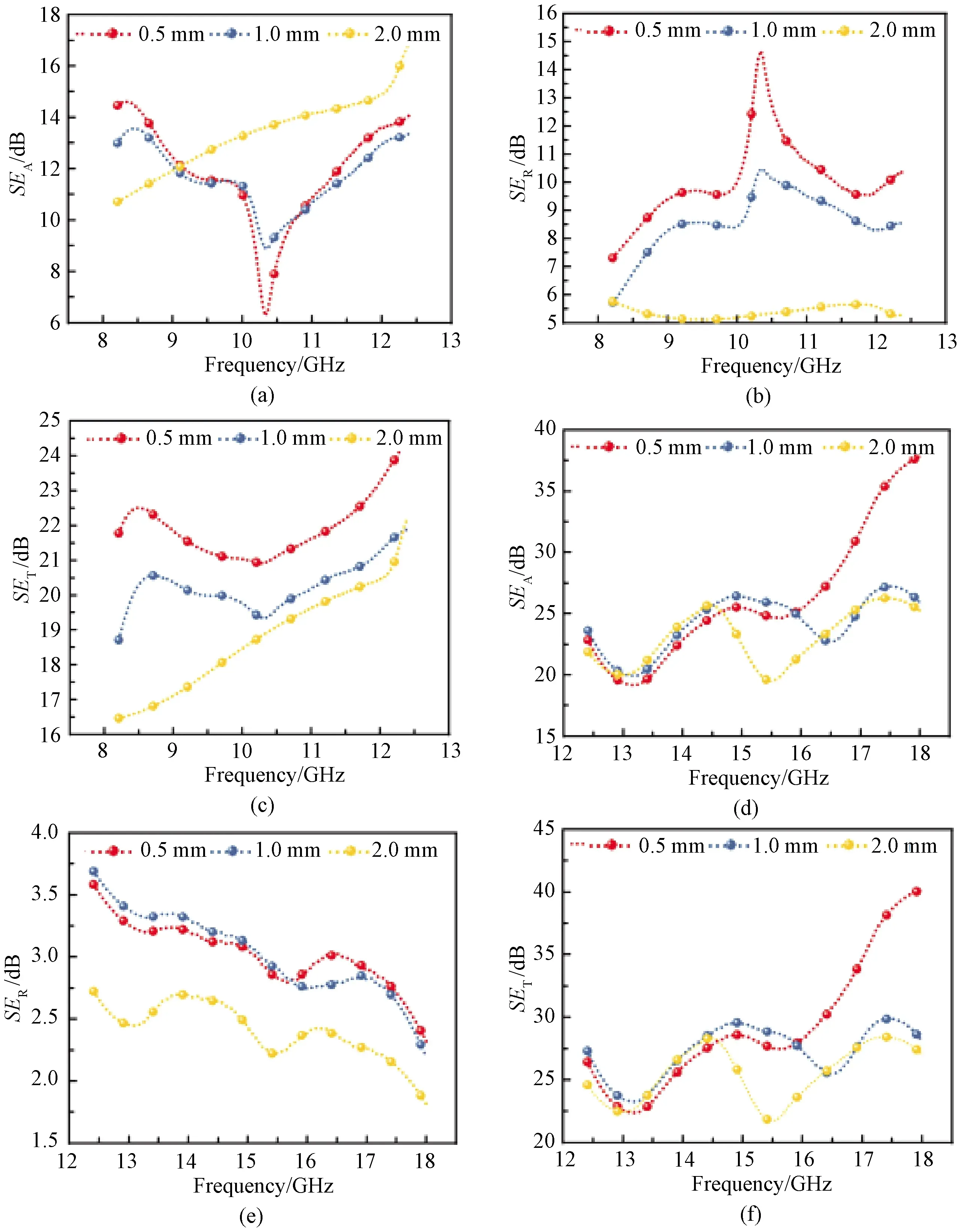

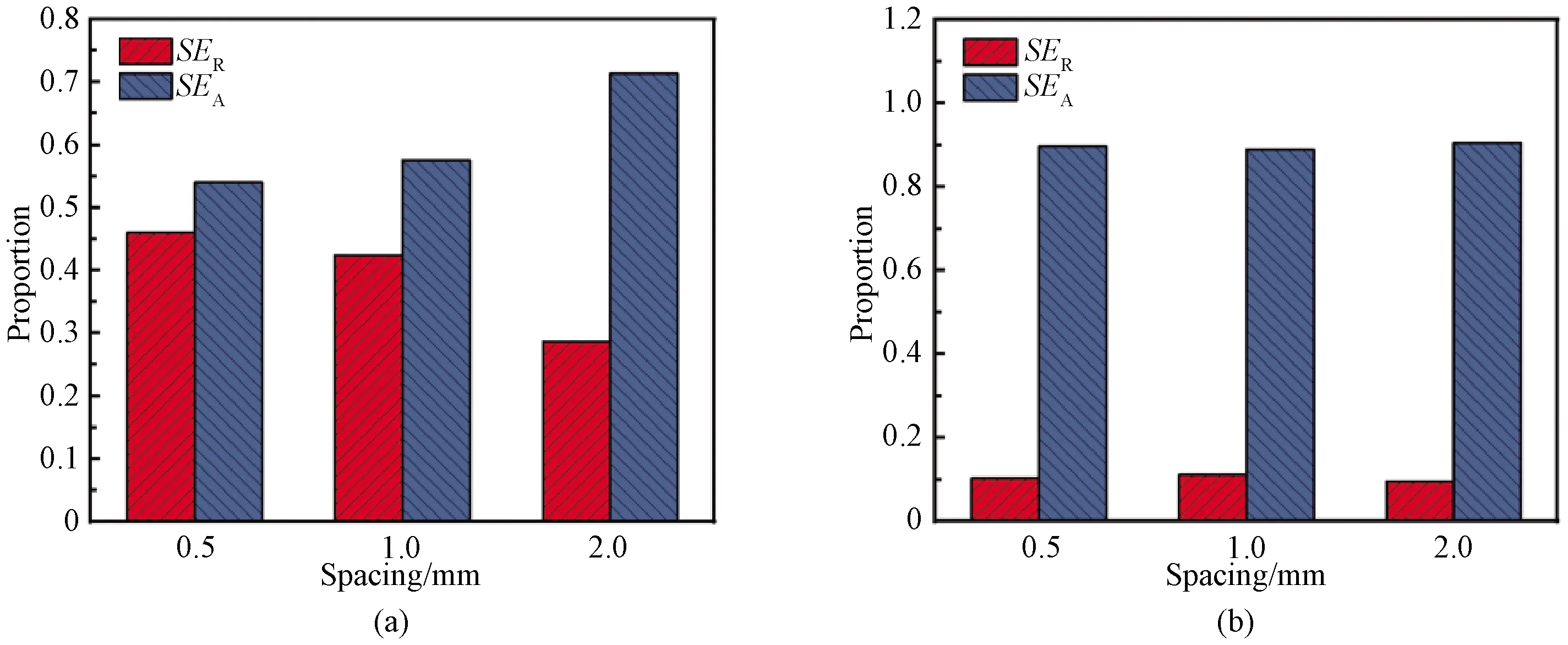

EMI electromagnetic shielding indicates the capability of the material to attenuate electromagnetic radiation[5].In general, multiple reflection(SEM)can be ignored when the total electromagnetic shielding is greater than 15 dB.Therefore, the total electromagnetic SE(SET)in this study is the sum of reflection loss effectiveness(SER)and absorption loss effectiveness(SEA)[13].As shown in Fig.3(c), the electromagnetic shielding performance of 3D metacomposites is inversely proportional to the spacing.As shown in Fig.4(a), the spacing has a great influence on the proportion of reflection and absorption.The ratio of reflection is inversely proportional to the spacing, and the absorption ratio is proportional to the spacing.

Fig.3 Electromagnetic shielding performance of 3D metacomposites with different spacings:(a)-(c)X band;(d)-(f)Ku band

Fig.4 Proportion of SER and SEA in 3D metacomposites with different spacings:(a)X band;(b)Ku band

In Ku band, the frequency dependence of reflection, absorption and electromagnetic shielding of 3D metacomposites with different spacings is close, which means that the spacing has little effect on the influence of frequency on electromagnetic shielding.The reflection and the absorption of electromagnetic shielding are related to the frequency, which can be characterized by[13]

SET=SEA+SER,

(6)

(7)

(8)

whereZandZ0are the impedances of the shield and air respectively,fis the frequency of the incident electromagnetic waves,μandσare the magnetic permeability of the shield and the electrical conductivity respectively,dis the thickness of the shielding material, andδis the skin depth[14].Therefore, the reflection decreases and the absorption increases as the frequency of incident electromagnetic wave increases to Ku band.The total EMI electromagnetic shielding increases.In addition, Fig.4(b)shows that the electromagnetic shielding mechanism is almost not affected by the spacing, and the reflection and absorption ratios of the three spacings are relatively close.The electromagnetic shielding mechanism dominated by absorption is obviously formed in 3D metacomposites with different spacings.

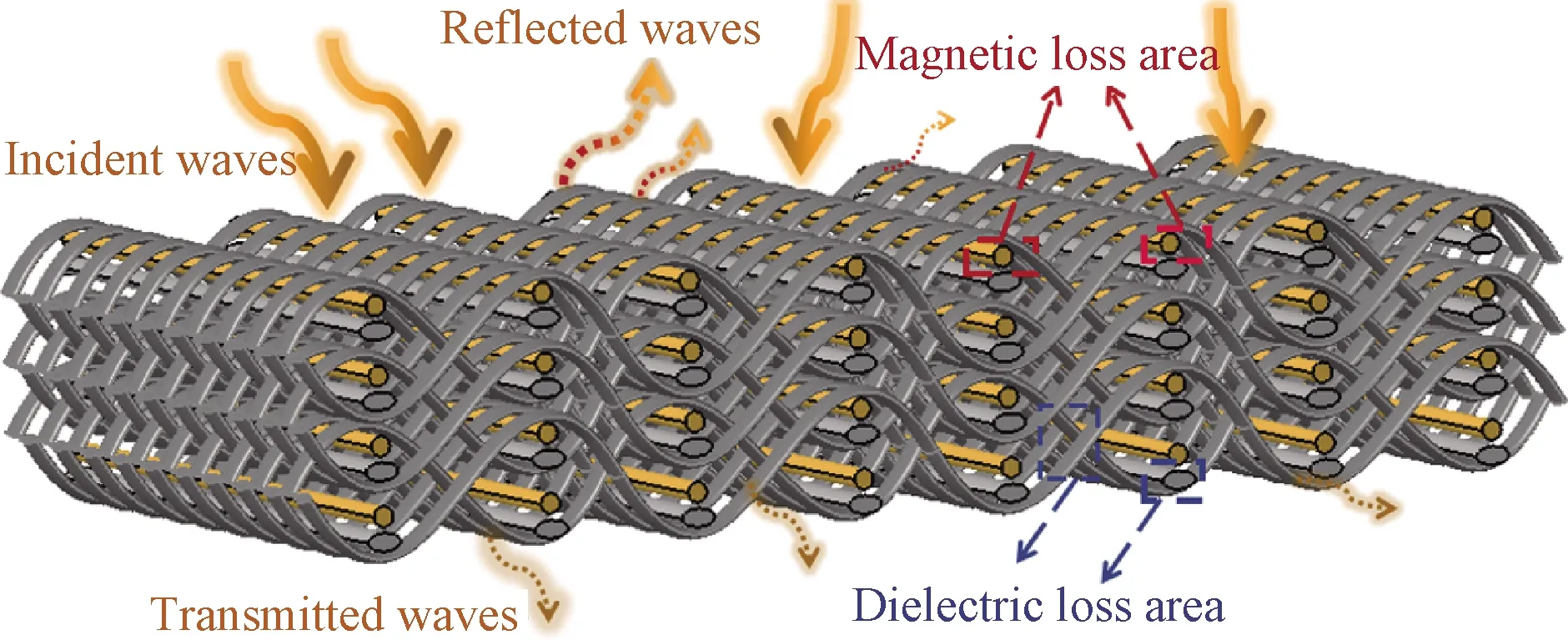

Figure 5 shows the electromagnetic shielding mechanism of 3D metacomposites.Generally, the reflection results from the impedance mismatch that occurs between the incident electromagnetic waves and the surface impedance of the shielding material.The absorption is mainly due to mobile charge carriers and electric and magnetic dipoles in the shielding materials[15-16].

Fig.5 Schematic diagram of electromagnetic shielding mechanism of 3D metacomposites

At high frequency, the magnetic loss is produced by the ferromagnetic microwires.The dielectric loss is produced by the quartz fibers.The incident electromagnetic wave is attenuated by the magnetic loss and the dielectric loss.In addition, the 3D metacomposite with ferromagnetic microwires has good impedance matching, which makes it easier for electromagnetic waves to enter into the shielding material, and finally reduces the surface reflection of electromagnetic waves.

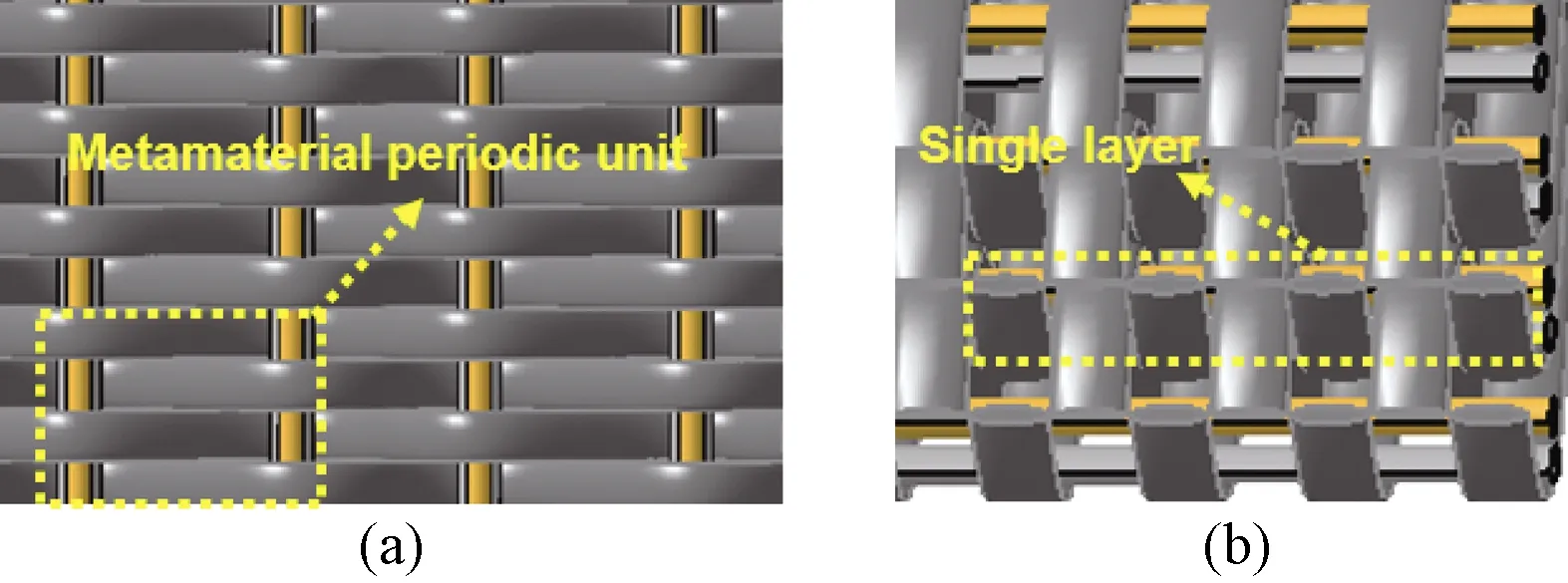

The electromagnetic performance of metacomposites comes from their periodic units.As shown in Fig.6, a 3D metacomposite periodic unit structure is composed of ferromagnetic microwires and quartz fibers by the 2.5D angle-interlock weaving method.When the electromagnetic wave is incident, the periodic unit structure will produce induced current and eventually attenuate the electromagnetic wave.The electromagnetic shielding mechanism based on absorption can reduce the secondary pollution of electromagnetic waves.

Fig.6 Structure diagram of periodic unit of 3D metacomposites:(a)top view;(b)side view

3 Conclusions

3D metacomposites with excellent electromagnetic shielding performance were prepared by combining ferromagnetic microwires with quartz fibers by the 2.5D angle-interlock weaving method.In X band, the ferromagnetic microwire spacing is inversely proportional to the reflection ratio and directly proportional to the absorption ratio.But in Ku band, the spacing has little effect on the reflection ratio and the absorption ratio.No matter which electromagnetic wave band the 3D metacomposite is in, its electromagnetic shielding mechanism is dominated by the absorption.The electromagnetic wave is greatly attenuated by the magnetic loss produced by ferromagnetic microwires and the dielectric loss produced by quartz fibers.The electromagnetic shielding mechanism dominated by absorption can reduce the secondary pollution of electromagnetic waves.

Journal of Donghua University(English Edition)2022年3期

Journal of Donghua University(English Edition)2022年3期

- Journal of Donghua University(English Edition)的其它文章

- Effects of Concentration of(3-Aminopropyl)Triethoxysilane on Waterborne Polyurethane

- Design of Creative Incentive Contract of Cultural and Creative Industry Chain from Dual Perspective

- Design and Synthesis of Acceptor-Donor-Acceptor Type Non-Fullerene Acceptors Using Oxindole-Based Bridge for Polymer Solar Cells Applications

- PbI2/Pb5S2I6 van der Waals Heterojunction Photodetector

- Health Monitoring of Induction Motor Using Electrical Signature Analysis

- Acquisition, Pointing and Tracking System for Shipborne Space Laser Communication without Prior Information