Synthesize of AZ31/TiC magnesium matrix composites using friction stir processing

*

aDepartment of Mechanical Engineering,Akshaya College of Engineering and Technology,Coimbatore 642109,Tamil Nadu,India

bDepartment of Mechanical Engineering,V V College of Engineering,Tisaiyanvilai 627657,Tamil Nadu,India

cDepartment of Mechanical Engineering,Roever College of Engineering and Technology,621212 Perambalur,Tamil Nadu,India

Synthesize of AZ31/TiC magnesium matrix composites using friction stir processing

M.Balakrishnana,*,I.Dinaharanb,R.Palanivelc,R.Sivaprakasamd

aDepartment of Mechanical Engineering,Akshaya College of Engineering and Technology,Coimbatore 642109,Tamil Nadu,India

bDepartment of Mechanical Engineering,V V College of Engineering,Tisaiyanvilai 627657,Tamil Nadu,India

cDepartment of Mechanical Engineering,Roever College of Engineering and Technology,621212 Perambalur,Tamil Nadu,India

dDepartment of Aeronautical Engineering,Karpagam University,Coimbatore 641021,Tamil Nadu,India

Friction stir processing(FSP)is a novel solid state technique to synthesize metal matrix composites.In the present work,an attempt has been made to synthesize AZ31/TiC magnesium matrix composites using FSP and to analyze the microstructure using scanning electron microscopy.A groove was prepared on 6 mm thick AZ31 magnesium alloy plates and compacted with TiC particles.The width of the groove was varied to result in four different volume fraction of TiC particles(0,6,12 and 18 vol.%).A single pass FSP was carried out using a tool rotational speed of 1200 rpm,traverse speed of 40 mm/min and an axial force of 10 kN.Scanning electron microscopy was employed to study the microstructure of the synthesized composites.The results indicated that TiC particles were distributed uniformly in the magnesium matrix without the formation of clusters.There was no interfacial reaction between the magnesium matrix and the TiC particle.TiC particles were properly bonded to the magnesium matrix.

Magnesium alloy;Friction stir processing;TiC;Microstruture

1.Introduction

Magnesium alloys are progressively replacing aluminum and steel in the aerospace and automobile industries and plastic in the electronic and computer industries due to low weight and good thermal and electrical conductivity.However, magnesium alloys are used for high performance applications due to their low mechanical properties and wear resistance. But magnesium reinforced with ceramic particles,known as magnesium matrix composites(MMCs)provide enhanced mechanical and tribological properties[1].It is diffcult to produce MMCs using conventional methods such as powder metallurgy,stir casting etc.

Friction stir processing(FSP)is a novel solid state technique to fabricate metal matrix composites[2].Mishra et al. [3]developed FSP,based on the principles of friction stir welding(FSW)to produce metal matrix composites.One method to produce composite using FSP is to prepare a groove of required depth and width,compact with ceramic particles, plunge the tool and traverse along the groove.The frictional heat softens the matrix alloy and the ceramic particles are dispersed within the plasticized matrix alloy due to the rigorous stirring action of the tool.

Some studies on the production of MMCs using FSP techniques were reported in literatures.Azizieh et al.[4]developed AZ31/Al2O3nano MMCs using FSP and studied the effect of tool rotational speed and pin profle on microstructure and particle distribution.Faraji and Asadi[5]produced AZ91/Al2O3nano MMCs using FSP and investigated the evolution of microstructure and microhardness.Sun et al. [6]fabricated AZ63/SiC nano MMCs using FSP and reported the details of the microstructure.

The objective of the present work is to synthesis AZ31/ (0,6,12 and 18 vol.%)TiC MMCs by applying FSP technique and study the evolution of microstructure.

2.Experimental procedure

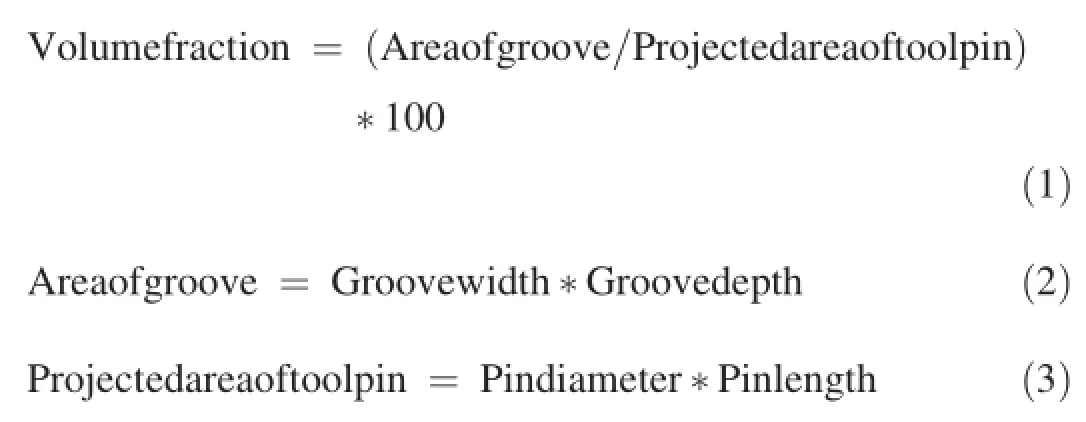

Magnesium alloy AZ31B plates(supplied by Luoyang Chenjin Magnesium Corporation Ltd,CHINA)ofsize 100 mm×50 mm×6 mm were used for this study.The composition of AZ31B is given in Table 1.A groove of 4.5 mm deep was made in the middle of the plate using wire EDM and compacted with TiC powder.The average size of TiC particles used in this work was 4 μm.The SEM micrograph of TiC particles is shown in Fig.1.A pinless tool was initially employed to cover the top of the groove after flling with TiC particles to prevent the particles from scattering during FSP.A tool made of HCHCr steel,oil hardened to 63 HRC was used in this study.The tool had a shoulder diameter of 18 mm,pin diameter of 6 mm and pin length of 5 mm.The FSP was carried out on an indigenously built FSW machine. The process parameters employed were:tool rotational speed of 1200 rpm,traverse speed of 40 mm/min and axial force of 10 kN.The FSP procedure to produce surface composite is available elsewhere[7].Four such plates were friction stir processed by varying the width of the groove(0,0.4,0.8 and 1.2 mm)to result in four levels of volume fraction of TiC particles(0,6,12,and 18 vol.%).The volume fraction was calculated according the expressions given below.

Specimens were obtained from the centre of the friction stir processed plates and were polished as per standard metallographic procedure.The polished specimens were etched with an etchant containing 4.2 g picric acid,10 ml acetic acid, 10 ml diluted water and 70 ml ethanol.The digital image of the macrostructure of the etched specimens was captured using a digital optical scanner.The microstructure was observed using a scanning electron microscope.

Fig.1.SEM micrograph of TiC powder.

Fig.2.Macrograph of AZ31/18 vol.%TiC MMC.

3.Results and discussion

AZ31/TiC MMCs were successfully synthesized using FSP. Fig.2 shows the macrograph of the FSP zone.A defect free FSP zone is observed.The FSP zone contains the composite. Typical FSW defects(tunnel,pin hole,piping and worm hole) are absent.It is evident from the macrograph that the groove is completely bonded to all sides.The pin length is 0.5 mm higher than that of the groove depth which is observed to be adequate to produce full penetration.Hence defects do not arise at the bottom side of the groove.The rubbing of the tool on the substrate generates frictional heat,which plasticizes the magnesium alloy which reaches the semi solid state.The vigorous stirring action of the tool distributes the packed TiC particles into the plasticized magnesium alloy.The translation of the tool moves the plasticized composite from advancing side to retreading side and forges at the back of the tool.The FSP zone on the retreating side is not clearly identifed by a boundary.The absence of clear boundary at the retreading side can be attributed to the material fow behavior of plasticized composite while forging at the back side of the tool to form the FSP zone.

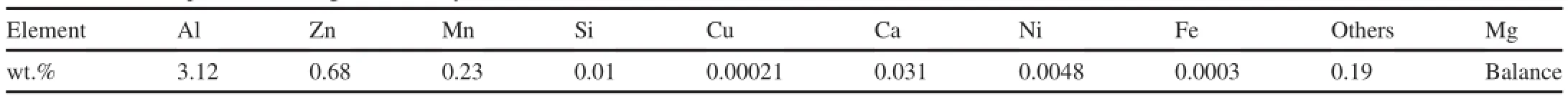

The effect of volume fraction of TiC particles on the microstructure of AZ31/TiC MMCs is shown in the SEM micrographs presented in Fig.3.Zero volume fraction refers to friction stir processed magnesium alloy which displays dynamically recrystallized grains.The SEM micrographs as presented in Fig.3 show the variation of microstructures as a function of volume fraction of TiC particles at 1000× magnifcation.The number of particles increases as well as the spacing between particles reduces when the volume fraction isincreased.The uniform distribution of TiC particles can be attributed to adequate generation of frictional heat,stirring and plasticized material fow across the friction stir processed zone.Mild agglomerations are also noticed at few locations. The variation in the distribution of TiC particles across the FSP zone was found to be negligible.The microstructure was independent upon the location in the FSP zone.This can be attributed to proper mixing and symmetric material fow during FSP.It is evident from Fig.2 that the FSP zone is almost symmetric about tool axis.

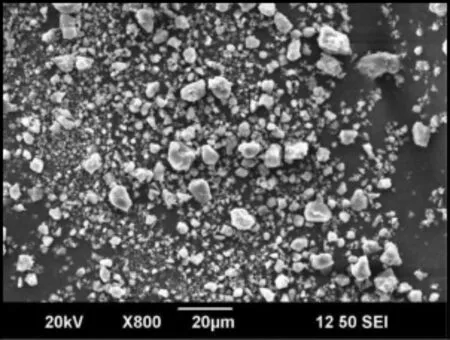

Table 1The chemical composition of magnesium alloy AZ31B.

Fig.3.SEM Micrograph of AZ31/TiC MMC containing TiC;(a)0 vol.%,(b)6 vol.%,(c)12 vol.%and(d)18 vol.%.

The TiC particles are subjected to the severe plastic fow of magnesium alloy during FSP.Several investigators observed a change in the size and morphology of ceramic particles during FSW [8].No such fragmentation of TiC particles was observed with the tooling and process parameters described within this work.The variation of TiC particle size in the composite as seen in Fig.3 is minimum and negligible.The variations in the morphology of the TiC particles before (Fig.1)and after(Fig.3)FSP are negligible.TiC particles retain the initial size and morphology.This can be attributed to the initial morphology and size of TiC particles which have a minimum number of sharp edges.

The interface between TiC particles and the magnesium matrix appears to be clean and is not surrounded by any voids or reaction products.Reaction products used to surround the particles if the composite is fabricated using the liquid metallurgy route.Since FSP is a solid state route,the temperature during the process is insuffcient to initiate any kind of interfacial reaction between the TiC particle and the magnesium matrix.A cleaner interface provides proper bonding between TiC particles and magnesium matrix and improves mechanical and tribological properties.Suffcient material fow and stirring create such a porosity free interface.

4.Conclusions

In the present work,AZ31/(0,6,12 and 18 vol.%)TiC MMCs were successfully synthesized using the novel method FSP.The microstructure of the composite was analyzed using scanning electron microscopy.The following conclusions were derived from the present work.FSP can be effectively used to synthesis AZ31/TiC MMCs without any kind of defects.TiC particles were distributed uniformly in the magnesium matrix without the formation of clusters.There was no interfacial reaction between the magnesium matrix and the TiC particle.TiC particles were properly bonded to the magnesium matrix.

Acknowledgments

The authors are grateful to the Management and Department of Mechanical Engineering,Coimbatore Institute of Technology,Coimbatore,India for extending the facilities to carry out this investigation.The authors are also thankful to Dr.N.Murugan and Dr.R.Sathis Kumar for their assistance offered to execute the above work.

[1]Y.L.Xi,D.L.Chai,W.X.Zhang,J.E.Zhou,Mater.Lett.59(2005)1831.

[2]H.S.Arora,H.Singh,B.K.Dhindaw,Int.J.Adv.Manuf.Technol.61 (2012)1043.

[3]R.S.Mishra,Z.Y.Ma,I.Charit,Mater.Sci.Eng.A 341(2003)307.

[4]M.Azizieh,A.H.Kokabi,P.Abachi,Mater.Des.32(2011)2034.

[5]G.Faraji,P.Asadi,Mater.Sci.Eng.A 528(2011)2431.

[6]K.Sun,Q.Y.Shi,Y.J.Sun,G.Q.Chen,Mater.Sci.Eng.A 547(2012)32.

[7]C.J.Lee,J.C.Huang,P.J.Hsieh,Scr.Mater.54(2006)1415.

[8]T.Prater,Mater.Manuf.Process 26(2011)636.

Received 25 November 2014;revised 19 December 2014;accepted 25 December 2014 Available online 31 January 2015

*Corresponding author.Fax:+91 4259 242570.

E-mailaddresses:balakrishnn0002@gmail.com (M.Balakrishnan), dinaweld2009@gmail.com (I.Dinaharan),rpalanivelme@gmail.com (R. Palanivel),rspkarpagam@gmail.com(R.Sivaprakasam).

Peer review under responsibility of National Engineering Research Center for Magnesium Alloys of China,Chongqing University.

http://dx.doi.org/10.1016/j.jma.2014.12.007.

2213-9567/Copyright 2015,National Engineering Research Center for Magnesium Alloys of China,Chongqing University.Production and hosting by Elsevier B.V.All rights reserved.

Copyright 2015,National Engineering Research Center for Magnesium Alloys of China,Chongqing University.Production and hosting by Elsevier B.V.All rights reserved.

Journal of Magnesium and Alloys2015年1期

Journal of Magnesium and Alloys2015年1期

- Journal of Magnesium and Alloys的其它文章

- GUIDE FOR AUTHORS

- Investigation and corrosion performance of cast Mg-6Al-1Zn+XCa alloy under salt spray test(ASTM-B117)

- Optimization of mechanical and damping properties of Mg-0.6Zr alloy by different extrusion processing

- A two-step superplastic forging forming of semi-continuously cast AZ70 magnesium alloy

- Dry sliding wear behavior of an extruded Mg-Dy-Zn alloy with long period stacking ordered phase

- Evaluation of physical and mechanical properties of AZ91D/SiC composites by two step stir casting process